Dr. Arafat’s research projects focus on developing sustainable desalination processes through innovative membrane technologies. This includes synthesis, characterization, and process testing of novel, high-flux and fouling-resistant membranes for desalination applications, especially in membrane distillation (MD) and reverse osmosis (RO). In addition, he has projects on system, economic, and thermodynamic modeling of MD processes. Below is a list of his current or recently completed research projects. Please click on the project title to see more details.

Novel Materials & Membranes

Hollow fiber membranes development for water and wastewater applications

Hollow fiber membranes and membrane module have been successfully employed in many industrial water, wastewater, and photocatalysis beverage processing as well as in pharmaceutical applications worldwide. Hollow fibers are particularly well suited to the high production demands of drinking water and wastewater treatment plants worldwide. Depending on the application, hollow fibers can operate with flows from “inside-to-outside” or “outside-to-inside” as seen in the following pictures. Regardless of flow pattern, hollow fiber membranes offer a compact, cost-effective solution for filtering large volumes of liquids utilizing minimal space and energy in the line of process intensification strategy.

In the MSDR group, we are using several techniques for HF membrane spinning including:

- Dry-Jet Wet Spinning, in which a polymer is dissolved in an appropriate solvent and extruded into air and a subsequent coagulant (usually water).

- Wet spinning, in which a polymer is dissolved and extruded directly into a coagulant (usually water)

The properties of the final membrane – such as average pore diameter and membrane thickness are finely tuned by changing the dimensions of the spinneret, temperature and composition of “dope solution” (polymer) and “bore fluid” (non-solvent), length of air gap (between spinneret and coagulation bath), temperature and composition of the coagulant, as well as the speed at which the produced fiber is collected by a motorized spool.

The main target areas of research we are focusing on for HF membranes at the MSDR group are: Membrane bioreactor, Photocatalytic membrane reactor, as well as high concentrated microalgae separation. Apart from that, we are also involved in surface modification of hollow fibre membrane with novel organic/inorganic materials for specific application starting from pharmaceutical waste degradation to biomass valorization. The image below shows an example SEM image of a HF membrane impregnated with photocatalytic nanoparticles for a special treatment application. Testing different configurations of membrane module and the optimization thereof is also part of our research.

Understanding and mitigating fouling in membrane distillation processes

Fouling is one of the main drawbacks of membrane-based desalination processes as it reduces the flux and the quality of the produced water. Although membrane distillation (MD) is not a pressure driven process and uses hydrophobic membranes that “repel water”, fouling and scaling processes occur, as our research has shown. In this project, we study the mechanisms through which fouling and scaling happen on the MD membranes, as well as the impacts of these fouling phenomena on the MD process. Our goal is to ultimately mitigate this problem by identifying guidelines for MD operation, synthesizing fouling-resistant membranes, and developing effective and practical protocols for cleaning fouled membranes. To do so, we start by characterizing the fouled membranes in terms of the morphological features relevant for the MD process, such as; pore size distribution, surface morphology, porosity, etc., as well as their change under MD operation. We then formulate a hypothesis about how fouling has occurred, after which we test the hypothesis using well-designed experiments. A number of advanced tools are used in this work including porometry equipment, scanning electron microscopy, surface contact angle tests, atomic force microscopy, and energy-dispersive X-ray spectroscopy (EDX), to name a few. Main findings of this project so far have been the confirmation of the occurrence of fouling by scaling as a result of intermittent MD operation. This has proven that the current dry-out practice of many solar-MD systems can be harmful to the membranes currently used. It has been also proven that the membrane material type and properties clearly play a role in this regard, which is yet to be carefully understood.

Right. SEM surface image of a PTFE membrane after exposure to seawater during 2 weeks. Severe fouling and membrane surface damage is observed. Left. EDX spectrum revealing a number of deposited salt compounds, including MgSiO3, MgCO3 and CaCO3 in addition to the NaCl.

Evolution of the contact angle (a measurement of hydrophobicity) with seawater exposure over 4 weeks. Values below 90º , observed after the second week, show that the membrane top surface has lost its hydrophobic nature with due to scaling.

Development of novel PVDF membranes by phase inversion for membrane distillation applications

Membrane distillation (MD) is a technique involving the Non-isothermal transport of fluids, especially water, through membranes. The major barriers hindering the full commercialization of this process include MD membrane and module design, membrane pore wetting, low permeate flow rate, flux decay with time, as well as uncertain energy and economic costs. These challenges have attracted scientists and engineers striving for the best membrane performance, module and process design, among which the selection of membrane materials was the most important. A key influence for the MD membrane is the fabrication procedures which influence the morphology and porosity, thereby defining the performance efficiency of fabricated membranes.

Polyvinylidenefluoride (PVDF) remains among the preferred options for MD membrane materials, because of the ease of PVDF dissolution in common organic solvents. As a result, porous PVDF membranes can be produced via phase inversion method. PVDF is a semi-crystalline fluoropolymer thermoplastic obtained by polymerizing vinylidene fluoride units. The major factor determining the type of phase separation that occurs for a system involving a semi crystalline polymer, such as PVDF, is the miscibility of the system, which is associated with the strength of polymer–diluents interactions. PVDF porous membranes can be easily produced by phase separation (i.e. phase inversion) process, simply immersing the cast solution film in a coagulant bath (i.e. non-solvent, frequently water). In this case, membrane porosity is controlled by additives in the casting solution (e.g., pore-forming agents) or by replacing water in the coagulation bath with a different non-solvent medium.

Additives can be used to impart pores, hydrophilicity, hydrophobicity, mechanical strength, antifouling properties and surface modification. A pore forming agent though diverse in the chemical nature is unanimous in it functional role of imparting a porous nature or enhancing the interconnectivity between pores. Pore forming agents do impart multifunctional effects, which may be synergistic or detrimental in end properties. A pore former can increase solution viscosity or accelerate the phase inversion process, to improve the membrane morphology, and to enhance the membrane separation as well as the performance.

In our research group, we are currently investigating the role of novel additives and process parameters in pore formation and also their influence on key membrane parameters such as morphology, hydrophobicity, Liquid entry Pressure [LEP], and pore size distribution [PSD], together with many other parameters such as mechanical strength and crystallinity. The final goal of the study is to identify and bring to practical application, suitable membranes which will stand the intricate demands of Membrane Distillation.

Various sophisticated analytical tools such as the Optical microscope and Scanning Electron Microscope [SEM] are used to unfold the structural constitution of the fabricated flat sheet and hollow fiber membranes. The pore characteristics are investigated using the Capillary Flow Porometry [CFP] and the surface interactions with water are evaluated using the Contact Angle Measurements.

Figure 1: Scanning Electron Micrographs [SEM] of flat sheet and hollow fiber PVDF membranes fabricated in our research facility

Development of novel corrugated PVDF membranes by phase inversion for membrane bioreactors

Membrane bioreactor (MBR) is the combination of a suspended growth bioreactor with a membrane process (e.g. ultrafiltration or microfiltration). It is now widely used for treatment of municipal and industrial wastewater. Even only a decade ago, membranes bioreactors were still an emerging technology and relatively novel within the municipal wastewater treatment industry. MBR processes, when used with domestic wastewater, can produce high quality effluent enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Moreover, MBR has many other advantages over the conventional processes include small footprint, and easy upgrade of old wastewater treatment plants. The membranes at the heart of the MBR technology easily become clogged with microorganisms and algae that grow on them – a process known as biofouling. Nothing can get through the membrane’s pores, making it no use as a filter for wastewater – so treatment has to stop for the membrane to be either cleaned or replaced. The loss of productivity, along with the cost of the treatment chemicals or new membranes, reduces the cost effectiveness of the MBR. A membrane that prevented biofouling could make MBRs a far more attractive option for water treatment. That is where our novel membrane comes in.

In our research group, we have created a membrane that is highly resistant to biofouling and also improves the through-flow of water. This was achieved by improving the membrane structure, porosity, and surface chemistry. The developed membranes were fully characterized before put into the test. This included, to mention some, contact angle, scanning electron microscopy, porosity and pore size distribution. In particular, our membrane has a pattern of valleys and hills on its outer surface that promotes turbulence in the water, which enhances movement of the wastewater through the filter. The 3D pattern also increases the effective filtration area of membrane, giving it twice the filter surface area – and therefore twice the productivity. Lastly and most importantly, the improved flow hydrodynamic makes it harder for unwanted organisms to stick to the membrane. To test our product, we placed our membranes in actual municipal wastewater gathered from Masdar City. Standard membrane bioreactor membranes need to be cleaned or replaced daily. After a month, our membranes were still fairly clear of biofouling and functioning as they should. In MSDR lab, we are currently in the process of further testing the membranes to understand the fouling mechanism and to find the best operation parameters that, in addition to the corrugations advantages, will result in the best conditions to maximize the fouling propensity.

Figure 1: Macro images of the spacers used to imprint the corrugated surface; fine (a) and coarse (d), top surface of the corrugated membranes: droplets-like surface (b) and diagonals-like surface (e), and side view picture of the membrane surface obtained using goniometer camera showing the topography of the droplets-like (c) and diagonals-like (f) corrugated membranes.

Figure 2: Long-term MBR filtration performance after one month of MBR operation showing a not-corrugated flat membrane (blue), and the two droplets-like and diagonals-like surface corrugated membranes (green and red, respectively).

Figure 3: Pictures (left end) and SEM-images of the fouled membranes. Deposition of foulants occurred mostly on the valleys area of the corrugated membranes.

PVDF membranes made using VIPS and NIPS pathways for membrane distillation

Phase inversion is one of the popular membrane fabrication techniques for membrane distillation applications. A recent study showed the importance of the solution composition pathway in the ternary phase diagram (Figure 1) on the hydrophobicity of the resultant membrane. The pathway is highly dependent on the membrane fabrication route, having on one side the complete non-solvent induced phase separation (NIPS) and on the other side the vapor induced phase separation (VIPS). These two extremes lead to two different membranes with different surface and in-situ properties (Figure 2). The NIPS membranes are characterised by low contact angle with low pore size, while VIPS membranes are characterised by high contact angle and high pore size.

The aim of our study is to tune the membrane properties by combining the NIPS and VIPS membrane fabrication techniques to achieve a superhydrophobic membrane with low bubble point diameter and a narrow pore size distribution. In this study the polymer of choice is Polyvinylidene fluoride (PVDF) and the solvent is Dimethylacetamide (DMAC). Water is used as a strong non-solvent for NIPS. We investigate the role of casting thickness together with the other variables in NIPS and VIPS to obtain the desired membrane properties. The VIPS process is carried out in a humidity controlled chamber.

An important part of the study is membrane characterisation. Surface scanning electron microscope (SEM) images are taken for all membranes to reveal their surface morphology and structure. Mean flow pore size, maximum pore size and the pore size distribution are measured using a capillary flow porometer. Contact angle measurements of deionised water are taken using a contact angle goniometer.

Preliminary results of the study showed superhydrophobic membranes could be obtained via the VIPS process with contact angles in the range of 140 – 145º. However, maximum pore size and pore size distribution of these membranes are still relatively high, in the order of 10 – 20 m, which renders them useless for membrane distillation (MD) applications. Currently the group is optimising the fabrication process to minimise the pore sizes and ultimately high flux and less wetting membranes for MD applications.

Figure 1: Ternary phase diagram of DMAC, PVDF and Water [1].

Figure 2: VIPS and NIPS.

References

[1] J. Mater. Chem. C, 2013, 1, 7695–7702

[2] Y. Peng et al. / Applied Surface Science 258 (2012) 7872–7881

Development of eco-friendly membranes from Poly(Lactic Acid) for applications in microfiltration and membrane distillation

In recent years, poly (lactic acid) (Figure 1) has drawn much research attention due to its environment friendly and thermoplasticity. Electrospun PLA mats have been studied in several applications, mainly as scaffold for biomedical application. However, the application of electrospun PLA in membrane applications is limited by its poor mechanical strength. In this project, electrospun PLA membranes were synthesized, modified by annealing or hot pressing, and characterized as candidate materials for membrane applications. This project was conducted in collaboration with Prof. Raed Hashaikeh from the Material Science and Engineering program at Masdar Institute.

Post annealing heat treatment was found to drastically change the membrane structure and properties. For example, with increasing annealing time or annealing temperature, membranes with smaller pore size, narrower pore size distribution, lower porosity (Figure 2) and lower contact angle were obtained. Also, both the tensile strength and elastic modulus improved significantly with annealing. Based on these properties, these membranes were proposed as microfiltration membranes. Vacuum filtration tests of a solution containing TiO2 particles were conducted. The filtration tests showed that the annealing treatment, which varied the membrane properties, had a significant impact on membrane performance, in terms of both flux and particle rejection. (Figure 3)

However, due to negative effect of annealing treatment on the membrane porosity and hydrophobicity, hot pressing was employed alternatively to improve the membrane properties for membrane distillation (MD). The effect of hot pressing temperature and pressure on the membrane structure, pore size and hydrophobicity were investigated. As the hot pressing temperature increases from 57˚C to 90˚C, smoother surface and lower contact angle with larger deviation were obtained, but with no significant impact on pore size. While in terms of hot pressing pressure, higher pressure leads to smaller pore size, with more consistent thickness and contact angle. We concluded that hot pressing is preferred from the view of pore size, porosity and contact angle for MD applications.

Figure 1: chemical structure of Poly(lactic acid) polymer

Figure 2: SEM images of electrospun PLA membranes. a) as-spun membrane, b) 30M-90C, c) 60M-90C, d) 90M-90C, e) 120M-90C, f) 30M-95C, g) 30M-100C, h) 30M-105C. (30M-90C means annealing treatment at 90°C for 30minutes). The image shows how the membrane pore structure can be tailored via post-spinning heat treatment.

Figure 3: Initial flux and average TiO2 rejection (left) and relative flux (flux, J, divided by initial flux, Jo) change with time (right of the as-spun, 30m-90C, 30m-95C and 90m-90C membranes. This shows how heat treatment was used to change the membrane performance as in a microfiltration application

Desalination Sustainability

Performance and economic modeling of membrane distillation processes

Membrane distillation (MD) has shown potential as a seawater desalination process. As a thermally driven membrane technology which runs at relatively low pressure and can tolerate feeds with high salinity, MD may be useful for desalination under condition for which reverse osmosis is not a good option. Moreover, solar-powered membrane distillation (SP-MD) desalination systems have been proposed as promising technology in off-grid areas with strong solar radiation. However, despite the various SP-MD pilot systems constructed and tested over the past two decades, such systems have not been commercialized or implemented on a large scale yet. Improved energy utilization and reduced water production cost in MD systems remain as important technical challenges. To promote the sustainability of MD, our main goal of this project is to provide insight on how the MD process can be better designed and optimized. This is achieved through MD system modeling and analysis. Our analysis includes thermodynamics, economical, and system design components.

In this project, the MD systems are evaluated in terms of several performance indicators, such as membrane flux achieved, energy consumption, gained output ratio (GOR), performance ratio, and the energy recovery scheme applied. A numerical model was constructed to evaluate how key performance parameters can be enhanced via certain operating parameters. The results of this study are used to suggest new areas of improvement for future MD projects. Economic evaluation is also carried out to understand the main contributors to water production cost in MD systems.

Finally, under this project, we also examine how optimization of the heat and mass transfer properties of the MD membrane can raise water flux and reduce specific energy consumption. Numerical modeling tools and factorial analysis are used to examine the effect of five MD membrane characteristics: porosity, tortuosity, thermal conductivity, pore diameter, and thickness. The water production cost (in USD/m3 of purified water) is calculated as a function of these parameters for an MD processes.

Impacts of membrane porosity and thickness on water production cost in an AGMD system operating using waste heat

Wind-Powered Desalination for Strategic Aquifer Water Storage in UAE

The development of strategic water reserves has been acknowledged as one of the main objectives to ensure water security, particularly in the GCC/MENA countries. In response to the lack of available water resources, the concept of storing desalinated potable water within an aquifer storage and recovery system (ASR) has been put to the table as a possible solution. However, since the intrinsic nature of an ASR makes it unnecessary to match the desalination production to the hourly or even daily water demand, renewably-powered water production become a “greener” and more affordable solution.

In order to draw conclusions regarding the feasibility of storing renewable-desalinated water, under this project, we conducted a techno-economic analysis. The scheme proposed was a wind-driven, variable load reverse osmosis plant that will produce water with a sole purpose of being stored. By variable load we mean that the RO’s load is allowed to vary in order to match the wind power fluctuations as the plant is not destined to meet a real-time demand but rather to create fresh water storage for long term security objectives.

This hypothetical scheme was assumed to have three components, as shown in Fig. 1. Those are 1) the wind farm, which will consist of wind turbines-along with their auxiliary equipment, 2) the RO plant and 3) the selected ASR site. The wind energy generation system would be used to power the variable load RO and will be the latter’s primary source of electrical power supply. Grid electricity will also be used to enable the plant to be continuously operating even at its minimum load. The purpose of the proposed scheme would be to produce a sufficient annual amount of desalinated water for recharge within a given period of time.

Figure 1: Schematic of Wind Desalination-ASR system

The methodology we followed included:

- Prime site identification using Geographic Information System (GIS) and the unique Wind Energy Resource Atlas of the United Arab Emirates (UAE), developed at Masdar Institute

- Design and performance simulation of a variable-load RO plant

- Cost analysis of the scheme to calculate the levelized cost of water (LCOW) and levelized cost of energy (LCOE)

The strategic storage of desalinated water in the UAE serves as a case-study to assess the technical and economic feasibility of the concept in the GCC region, historically known for low utilization rates of wind energy. The preliminary selection of feasible areas (“feasible zones”) is shown for the western as well as the eastern region of Abu Dhabi (Fig. 2). Most of the coastal area west of Abu Dhabi is included in the feasibility zones due to its low slope and the absence of settlements in this territory.

Figure 2:Feasibility Zones for Wind-RO development, shown for the western region of the UAE

Cost Analysis of Renewable-Energy-Powered Desalination

Rapid economic growth, rise in population size and water scarcity have led many countries in the world to utilize seawater and brackish water desalination as a means to offer water of acceptable purity to their citizens. The fossil fuels were and still are the main sources of energy for desalination in many regions around the world. However, as they have been blamed for contributing to the climate change and global warming, alternative sources of energy such as wind, solar, biofuels and many other have been introduced. Fortunately, most of these sources of energy have been examined for various applications in daily life and have been proven for their functionality

This research focuses on evaluating the monetary costs of renewable desalination. Even though, the idea of renewable energy replacing conventional fossil fuel for power generation is not new, yet its implementation in the desalination industry has been limited due to a number of reasons. One of the reasons preventing a more widespread use of renewables in the energy-intensive desalination processes is the high upfront investment required and the uncertainty regarding the final cost of produced water. Thus, exploring and cost modelling the application of renewables in desalination by itself is a challenging task. Cost analysis of renewable energy desalination will be an important tool for the decision-makers that shall increase the knowledge and will allow them to benchmark the economic feasibility of ‘green’ solutions.

One of the possible couplings of renewables and desalination is geothermal reverse osmosis (RO). In our ongoing research in this area, a complete scheme for this coupling is being designed, with flows of energy, mass and size of equipment numerically calculated and cost-modeled. The capital cost (CAPEX) of reverse osmosis was one of the parameters that had to be defined to assess the overall water production cost under this scheme. Parameters potentially affecting the direct capital costs of brackish water RO (BWRO) and seawater RO (SWRO) desalination plants, delivered through Engineering, Procurement & Construction (EPC) contracts, were assessed. The assessment was conducted based on cost data from 950 RO desalination plants contracted in the Gulf Cooperation Council (GCC) countries and in five southern European countries by different EPC contractors (See Figure 1). The parameters assessed include plant capacity, location, award year, feed salinity, and the cumulative installed capacity within a region installed by various companies [1]. Our results showed that plant capacity has the strongest correlation with the EPC cost. Plant type (SWRO or BWRO), plant award year and the region of the RO plant were also found to be statistically important. By utilizing multiple linear regression, a model was also developed to estimate the direct CAPEX (EPC cost) of RO desalination plants to be located either in the GCC countries or southern Europe, which was then verified using the k-fold test (See Figure 2). Full details of this CAPEX modeling cost can be found in our paper published in Desalination Journal in 2014 [1]. More results are due for publication shortly.

[1] S. Loutatidou, B. Chalermthai, P. R. Marpu, H. A. Arafat, Capital cost estimation of reverse osmosis plants: GCC countries versus southern Europe, Desalination, 347, 103-111 (2014)

Figure 1: Normalized EPC cost from 1985 to 2013 for three of the leading companies (in terms of number of contracts) in the respective region and for the shown type of RO plant

Figure 2: Overall Model fit (simulated and predicted values plotted in a common graph)

Reducing the environmental impacts of desalination processes using Life Cycle Analysis (LCA) tools

As desalination technologies have been shown to be associated with considerable environmental impacts, environmental considerations are the drive behind a number of recent process changes in desalination plants. Commonly, the main contributors to these environmental impacts in desalination include energy consumption, water intake, brine discharge, and chemical usage. One tool to assess the environmental impacts of desalination processes is by conducting Life Cycle Analysis (LCA). LCA allows us to quantify the environmental gains (or losses) incurred by shifting from one design choice to another within a desalination plant. An LCA study considers all the environmental impacts associated with a product or system throughout its life cycle (i.e., from cradle to grave).

To date, two major studies were conducted under this project within our group. In the first study, we assessed and compared the environmental impacts of three alternatives for supplying desalinated water to remote off-grid communities within the United Arab Emirates (UAE). Two alternatives are via autonomous solar-powered water desalination systems, compared to a third option where water is supplied from a central Reverse Osmosis (RO) desalination plant. The three options are: (1) a solar still, (2) a solar photo-voltaic powered RO system, and (3) water delivery by tankers from an existing RO plant. In the second study, two systems for intake water pretreatment (for fouling control) in RO desalination plants were compared: sedimentation-based and membrane filtration pretreatment systems. We assessed and compared the environmental impacts of both alternatives using design and operational data for the sedimentation based system from the Fujairah-1 plant (in UAE). The alternative ultrafiltration system was fully designed to retrofit the current sedimentation system at Fujairah. By use of LCA, a comprehensive environmental modeling of the considered options for both case studies was conducted.

By comparing the sedimentation and ultrafiltration pretreatment processes, the latter scenario was shown to have reasonably lower environmental impact. The main driver behind these results was the difference in energy consumption, which is behind the major part of the environmental impact (Figure 1).

Figure 1: Breakdown of contributors to the overall impact in sedimentation based pretreatment

Sustainable Solutions for Arid Regions

Sustainable Greenhouse Solution for Arid Regions within the Food-Water-Energy Nexus

“By 2025, 1.8 billion people will be living in countries or regions with absolute water scarcity, and two-thirds of the world’s population could be living under water stressed conditions”

- UN Water Policy Brief 2011

Water security is an issue that is present globally. It may have varying degrees of severity, but the use of the term “security” infers an inability to meet water needs both inter and intra generationally. The ability to secure a water source has been paramount to the successful functioning of civilisations throughout history. The provision of freshwater becomes an increasingly burdensome problem for arid regions, such as the UAE, whereby inter-related issues like food production, resource security, population growth and climate change are heavily involved in the solution hierarchy. One of the key dynamics that is currently being explored in this hierarchy is known as the Food-Water-Energy (FWE) nexus. In order to meet global demand in 2050, the International Renewable Energy Agency (IRENA) has estimated that food production will need to increase by 60%, water availability by 55% and energy generation by 80%. It is therefore with pressing urgency that solutions be designed to meet this growing demand.

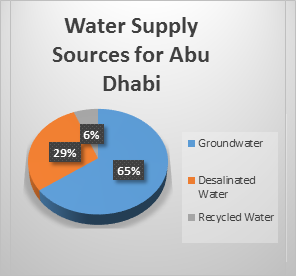

Figure 1: Overview of Supply and Demand Characteristics of Abu Dhabi’s Water Sector

When we examine the sectors in which we use water, it becomes vividly clear that agriculture is most commonly the largest consumer. As can be seen from Figure 1, this represents some 56% of consumption in Abu Dhabi, with 65% of this supply coming from groundwater. This places a large stress on groundwater aquifers in a region where the average renewable water resources are less than 100 m3 per capita, compared to a global average of 6000 m3 per capita. The majority of this water use is for irrigation. The practice of open field irrigation can lead to its own problems such as salinization of soil, loss of soil fertility and structure, non-optimal fertiliser uptake etc. These negative environmental impacts occur in parallel with a growing salinity of the groundwater supply. So the question becomes; what solution can be applied to deliver a sustainable agricultural system that can produce food, but not lead to overconsumption of water and energy resources?

The intended result of this research project is to provide such a solution. With the application of greenhouse technology, in conjunction with a desalination system, the goal is to provide a computational model that will aide in the design of optimal solutions for the sustainable production of food in arid regions with a saline groundwater feed. On this basis, the solution is referred to as the sustainable greenhouse.

Greenhouse technology has many beneficial characteristics, especially when we consider that the target region for the sustainable greenhouse solution is an arid environment with a saline water source. Providing a controlled environment, that has been engineered to operate in otherwise restrictive conditions, as compared to open field cultivation, provides the opportunity for agricultural systems to operate with significantly less risk. Presently, there are approximately 38,500 farms in the UAE, of which an estimated 24,000 are in Abu Dhabi. Conversely, Abu Dhabi occupies 86.7% of the total area of the UAE, excluding the islands, but it has only 5.4% of the total cultivable land in the country. Collectively, these farms produce just 15% of domestic food requirement. However, the value of this agricultural activity is estimated to be Dh10 billion per annum. It is clear that there is an opportunity for a large agricultural sector in the UAE economy, and that there is a need to make it sustainably viable in the given environment. The sustainable greenhouse solution that will be examined in this project is aiming to achieve both of these goals symbiotically.

Development of strategies for sustainable municipal solid waste management in the UAE

Waste and water are two inter-related elements of sustainable urban development. Solid waste materials usually have a significant water footprint (virtual water content), which presents the amount of water that went into producing those wasted materials in the first place. Reducing the amount of waste is a significant indirect way of increasing the availability of precious fresh water, which is probably created through a desalination process to start with. However, the research tools needed to deal with solid waste are very different from those employed in desalination research, although they can be just as creative and exciting!

Waste management has to do with the collection, storage, and disposal of waste. It is crucial that modern cities have a well-developed waste management system, especially from the perspective of sustainability. Abu Dhabi (UAE) is no exception. In fact, Abu Dhabi’s rate of waste generation is higher than that of many other countries and the emirate has already lost 1,800 hectares of land to landfills. Currently, more than 75% of the waste produced in the UAE ends up in landfills. This has many negative consequences. For example, half of camel deaths in the UAE are due to suffocation by littered plastic bags. Abu Dhabi aims to divert 90% of its waste from landfills by 2018 and a member of our research group is working to help facilitate reaching this goal.

The hospitality sector in the UAE is forecasted to grow at more than 10% annually over the next four years, greater than the predicted rate of the growth of the overall Arabian Gulf market. Moreover, the Abu Dhabi Tourism Authority (ADTA) has aimed to reduce the amount of hotel waste going to landfills by 20% as a first step in its environmental program. This waste includes food waste, which is the most significant component of hospitality waste. The issue of food waste is a global problem, and is an area on which little research is done. This problem is particularly significant in Abu Dhabi. What is more, food waste is one of the most important materials to divert from landfills, due to the fact that it decomposes to create methane, a potent greenhouse gas which significantly contributes to climate change. In addition, by targeting the hospitality industry, a smaller sector (relative to households) may be focused on, but one that tends to produce more food waste per capita. Along the same lines, the initial implementation of policies and subsequent follow-up actions would be easier in the hospitality sector than in households.

This research aims to focus on the area of food waste management in the hospitality industry, with an emphasis on the situation in the Middle East region, especially the United Arab Emirates. It will include the development of food waste management strategies which not only address the handling of the waste once it has been produced, but also explore waste minimization, taking into consideration factors such as the culture of this region. Relevant strategies/measures being implemented in developed countries would be studied, and with input from local environment and waste management stakeholders, it would be explored how such measures may be implemented in the UAE and beyond. The study involves close interaction with various institutions in the UAE: the Environmental Agency Abu Dhabi, Abu Dhabi Tourism Authority, the Center of Waste Management Abu Dhabi, waste management companies such as Averda, and various hotels and restaurants.